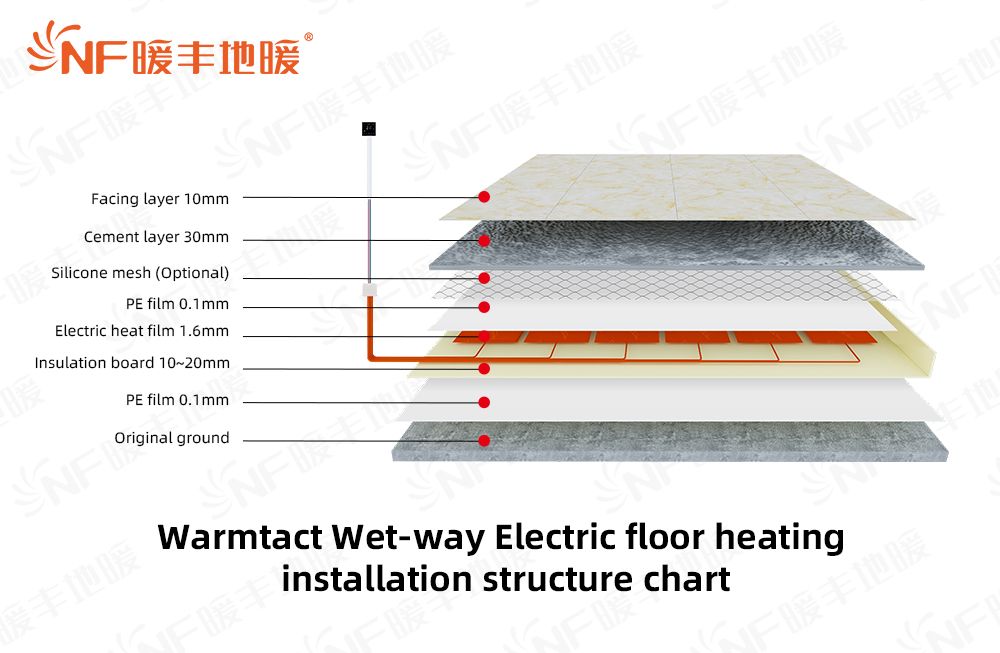

The eighth generation of electric floor heating has not only been upgraded in the internal and external structure of the product, but also changed in the installation structure. According to the installation process, there are seven layers from bottom to top, so what is the role of each layer? What are you noted when installing?

Here's the explanations.

Layer 1: PE film

PE film, all known as "polyethylene film". This layer of PE film is specially customized, it has the characteristics of good heat resistance, small moisture permeability and so on, waterproof, moisture-proof performance, can prevent the ground moisture or moisture, affect the heat insulation effect of the insulation board.

Layer 2: Insulation layer

The insulation layer can prevent the heat transfer of floor heating, so as to reduce the ineffective heat loss, thus reducing the operating cost of the floor heating system. At present, there are two kinds of commonly used floor heating insulation board on the market: XPS and PUR. When laying the insulation board, the seam needs to be staggered, the gap is controlled within 5mm and fixed with tape to prevent displacement.

Layer 3: Electric heating film for wet floor heating

Electric heating film belongs to the facial heating body, which can evenly and quickly heat the floor during operation. In order to ensure the overall performance of the electric film floor heating, electric film floor heating when laying need in strict accordance with the construction drawings, a positive logo face up, electric film and electric film spacing to be consistent, and to lay flat, no wrinkles, distortion, then need to use tape to electric film fixed on the insulation.

Layer 4 & layer 5: PE thin film & silicon crystal grid

This layer of PE film is mainly used to protect the electric film, which can avoid the direct contact between the cement mortar and the electric film, and improve the stability of the floor heating system.

As for the middle of the filling layer, the silicon crystal grid can increase the strength of the ground, play a role of anti-crack, and effectively avoid the floor cement cracking.

Layer 6: Filling layer

The filling layer can play a role in heat storage, protecting and fixing the floor heating, and leveling the ground. In order to prevent breaking the electric thermal film, the general filling layer material will use leguminite concrete, leguminite particle diameter between 5 and 12 mm. The thickness of the filling layer is recommended to be about 30~50mm.

Layer 7: Facing layer

After the installation of the warmtact wet-way floor heating, the owner can choose ceramic tile, marble or wood floor as the ground decorative layer. It should be noted that the thickness of the surface layer should be controlled at 1~2cm, otherwise it will affect the heat transfer effect of floor heating. If you want to lay the wood floor, then you must choose special wood material with heat resistance, heat conductivity of better heating.

400-888-6336

400-888-6336